Why Powder Coating is the Most Sustainable Finish for Industrial Applications

Powder Coating is widely regarded as one of the most environmentally friendly finishing processes for industrial applications. Unlike traditional liquid coatings, powder coatings offer numerous advantages that make them a sustainable choice for manufacturers and end-users alike. In this article, we will explore the reasons why powder coating stands out as a sustainable solution, addressing key benefits such as waste reduction, energy efficiency, and its long-term performance in industrial environments.

Key Benefits of Powder Coating in Terms of Sustainability

Powder coating provides significant environmental benefits compared to conventional liquid paint. Below, we examine the key reasons why it is considered the most sustainable finish for industrial applications.

1. Minimal Waste Generation

One of the most significant advantages of powder coating is the extremely low level of waste it generates. Unlike liquid coatings that often produce excess paint that cannot be reused, powder coating overspray can be easily reclaimed and reused. This drastically reduces material waste and ensures that almost all of the applied material contributes to the finished product.

| Waste Factor | Powder Coating | Liquid Coating |

| Material Waste | < 5% | 30-50% |

| Reusability of Overspray | 100% | 0% |

2. No Solvents or Harmful Emissions

Powder coatings do not require the use of solvents, which are commonly found in liquid coatings. As a result, they do not emit volatile organic compounds (VOCs), which contribute to air pollution and pose a health risk to workers. This makes powder coating an ideal solution for industries striving to meet increasingly stringent environmental regulations.

3. Energy Efficiency

Powder Coating Processes are typically more energy-efficient than traditional painting techniques. The curing process of powder coatings often requires lower temperatures and less time than liquid coatings, leading to reduced energy consumption in the finishing process. Furthermore, many modern powder coating systems use energy-efficient equipment, such as electrostatic spray guns, which reduce energy use without compromising application quality.

4. Durability and Longevity

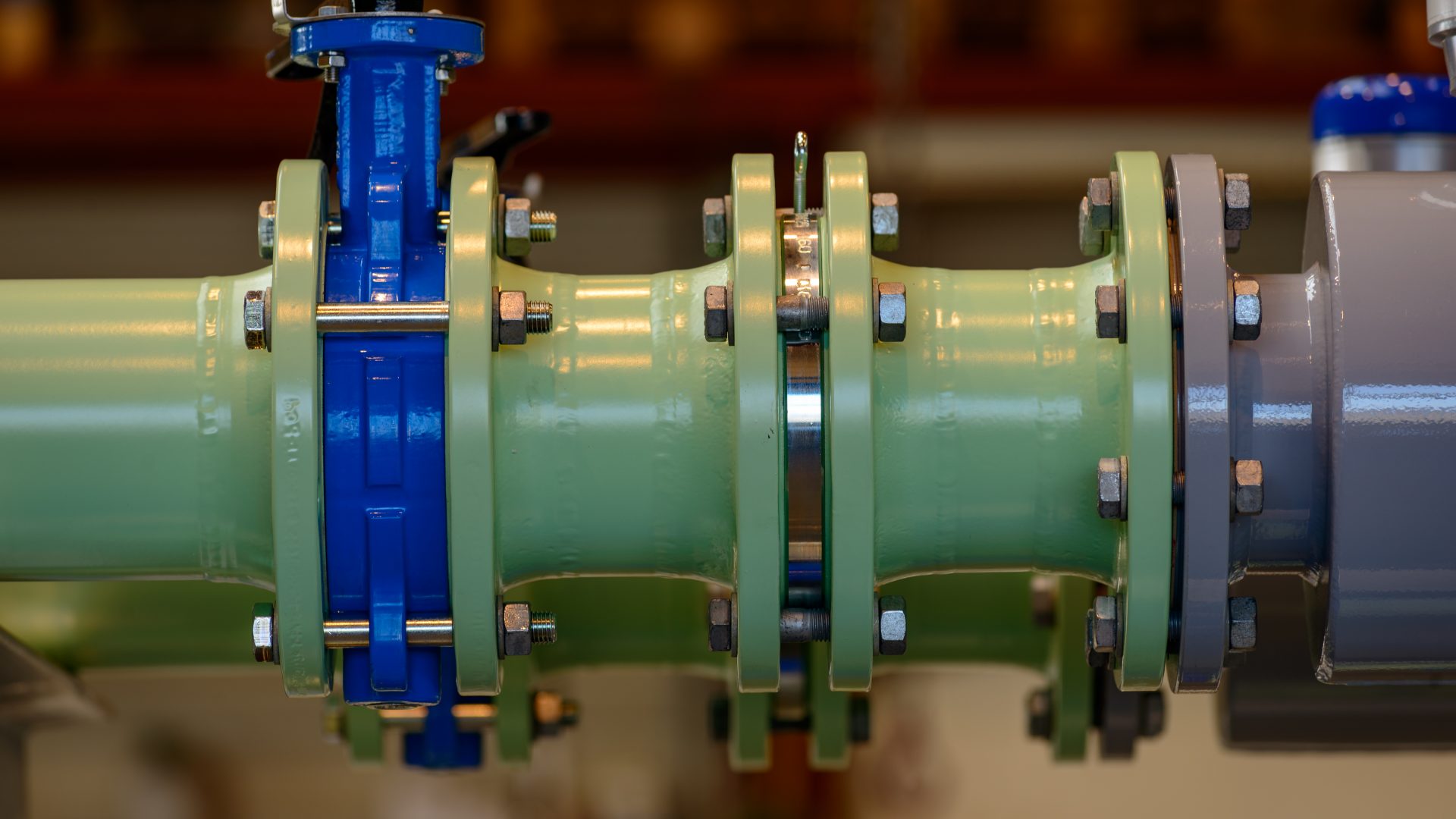

The durability of powder coatings also plays a crucial role in their sustainability. Powder-coated surfaces are highly resistant to wear, corrosion, and weathering. This increases the lifespan of products, reducing the need for frequent re-coating and, consequently, decreasing the environmental impact associated with coating maintenance and replacement. Powder coatings can endure harsh environments, making them ideal for industries such as automotive, architecture, and heavy machinery.

5. Reduced Water Usage

Traditional liquid coatings often require the use of water-based solutions for cleaning and preparation. In contrast, powder coating uses minimal water and avoids the need for hazardous cleaning chemicals, thus conserving water resources and preventing contamination from harmful substances.

6. Recyclable and Non-Toxic

Powder coatings are non-toxic and free of hazardous substances like lead and chromium, making them safer for both workers and the environment. Additionally, the powder itself can be easily recycled, further reducing the environmental impact of the finishing process. The materials used in powder coatings are often made from recyclable ingredients, contributing to a circular economy.

7. Lower Carbon Footprint

By reducing waste, minimizing harmful emissions, and lowering energy consumption, powder coating processes significantly lower the carbon footprint of manufacturing operations. This makes powder coating an important part of a company's sustainability strategy, particularly as businesses seek to meet their corporate social responsibility (CSR) goals and reduce their overall environmental impact.

Frequently Asked Questions

1. What are the environmental benefits of powder coating over liquid painting?

Powder coating is free of solvents, emits no VOCs, and generates less waste than traditional liquid paint. This makes it a cleaner, more sustainable option for manufacturers, contributing to reduced pollution and energy consumption.

2. Is powder coating more expensive than traditional liquid coatings?

While the initial equipment costs for powder coating systems can be higher, the long-term savings in material usage, energy efficiency, and reduced maintenance costs make it a more cost-effective solution over time.

3. How does powder coating improve the durability of products?

Powder coating provides a tough, durable finish that resists chipping, scratching, fading, and corrosion. This longevity reduces the need for frequent re-coating, making it more sustainable in the long run.

4. Can powder coating be used on all materials?

Powder coating can be applied to a variety of metals, including steel, aluminum, and iron. However, it may not be suitable for certain substrates such as plastic or glass without proper surface preparation.

5. How can I ensure the sustainability of my powder coating operation?

To ensure sustainability, businesses should invest in efficient equipment, implement material reclamation systems, and focus on reducing energy consumption. Choosing high-quality, recyclable powder coatings also contributes to sustainability.

Conclusion

Powder coating offers numerous environmental advantages over traditional liquid coatings. From minimal waste and VOC-free emissions to improved energy efficiency and long-lasting durability, it represents one of the most sustainable finishing solutions available. By adopting powder coating, manufacturers can reduce their environmental impact, lower operational costs, and increase the longevity of their products, making it a smart choice for both business and the planet.